Insulated Rubber & Plastic Cover up

Relevant Standard ASTM F1236

Line hose and covers are required to be tested when insulating value is suspect of damage, blankets should be tested before first use and every 12 months after.

Relevant Product Information

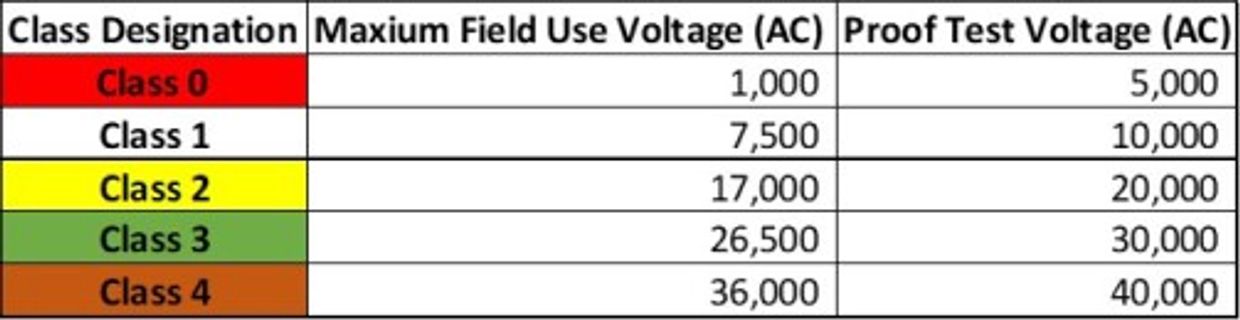

Insulated Rubber & Plastic comes in the following Classes 0, 1, 2, 3, 4.

There are two types of rubber produced when making line hoses and blankets:

Type 1: nonresistant to ozone, made from high-grade rubber compound of natural or synthetic origin, properly vulcanized

Type 2: ozone resistant, made of any elastomer or combination of elastomeric compounds

Cleaning of Rubber & Plastic Cover up

Cleaned by hand in wash tank with approved detergent & air dried

Visual Inspection of Rubber & Plastic Cover up

Inspection of rubber for cuts, punctures, foreign objects (metal filings, wood slivers)

Electrical Test of Rubber & Plastic Cover up

Insulated rubber & plastic cover up is tested at 1 minute based on its classification. Example Class 2 rubber or plastic is a 1 minute test at 20,000 volts. A pass for the electrical test would be no flash over through rubber or plastic equipment.

Failure Modes of Rubber & Plastic Cover up

Electrical failure in blankets particularly class 4.

Pole covers and lines hoses have a low rate of failure and typically only fail when a hole is present from mechanical damage.

Storage & Care of Rubber & Plastic Cover up

Visual inspection of blanket before use, keep rubber/plastic goods off ground, clean off rubber/plastic goods if it becomes contaminated (oil, mud, etc.) with cleaning product.

Insulated rubber and plastic goods should be stored in plastic or cloth and have a designated storage spot.

Do not Fold (Blankets)

Do not place any objects on top (Blankets)

Store in relaxed or normal position (Line hose)

CLICK LINK BELOW FOR INFORMATION ON OUR TooL EXCHANGE PROGRAM

Tool Exchange Program

Tool Exchange Program

Copyright © 2020 Western High Voltage Test Centre - All Rights Reserved.