Bond Mats

Relevant Standard ASTM F 2715

Bond Mats are recommended to be tested annually or if damage is suspected.

Relevant Product Information

Bond mats come in a range of sizes depending on requirement. Typical grid size is 5'X10' or 10'X10'.

Cleaning of Bond Mats

Bond mats are hand washed and air dried.

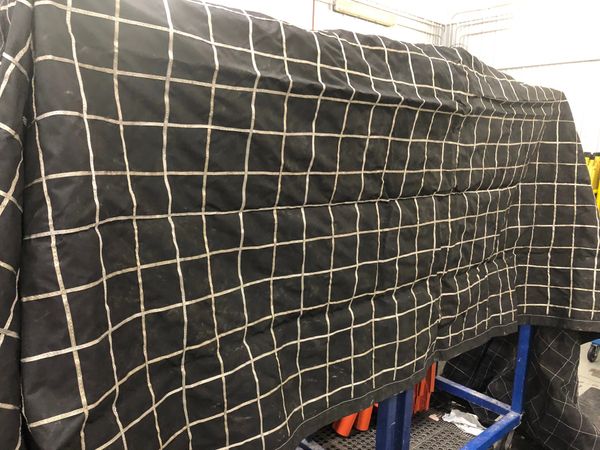

Visual Inspection of Bond Mats

Bond mats are visually inspected for damage to insure the metal mesh that comprises the bond mat grid is intact. The cable, ferrule and clamp connection are also inspected.

Electrical Test of Bond Mats

Bond mats are tested with a Digital Low Resistance Ohm Meter which provides a source producing a measured resistance. The measured resistance is compared to the expected calculated resistance and the bond mat is passed or failed.

Failure Modes

Due to the nature of work and how Bond mats are used they are susceptible to damage when workers are walking on them. Failures of Bond mats can be from visual failure due to the mesh grid being damaged. If the damage is minor the bond mat can be repaired.

Storage & Care of Bond Mats

Keeping bond mats clean is important so it remains functional in operation. Cleaning off debris before use is recommended.

Bond mats should be stored in a dry area and not have anything stored on top of them to avoid damage.

.jpg/:/rs=w:600,cg:true,m)

Before Cleaning Bond Mat

After Cleaning Bond Mat

Copyright © 2020 Western High Voltage Test Centre - All Rights Reserved.